Foundation troubles hardly ever reveal on their own along with a solitary sign. A small stair-step fracture at a brick edge commonly join a difficult door, or a piece that once experienced solid now has an unfilled faucet. In commercial settings the range adjustments yet the design hosts. Settlement telegrams via cladding, interior finishes, as well as equipment positioning. When dirts can certainly not bring load, or groundwater always keeps changing the design beliefs under your structure, superficial solutions run out of roadway. That is actually when deep foundation repair actions from possibility to necessity.

I have actually invested years around task trailers, boring gears, twist indicators, and soils logs. Deep-seated job looks well-maintained abstractly, but in the business it is actually a dancing along with restraints: limited get access to, reside procedures, unknown filler, buried utilities, sound home windows, twist refusal at 2 in the morning. The ideal service is actually hardly a single item. It is a series, part architectural, part geotechnical, in some cases component surgical demo, along with continuous confirmation that weight is in fact going where you mean. This write-up sets out just how our experts analyze, choose, as well as implement the primary tools in the kit: helical piles, protection heaps, micropiles, and also helical tieback anchors. Along the way, our experts will mention foundation crack repair, basement waterproofing tie-ins, and also the efficient side of business foundation stabilization.

What failure looks like, as well as why the ground is actually frequently innocent

The ground performed certainly not set bent on neglect your structure. Generally the design or the operations transformed. Aquifer relocate after stormwater enhancements upstream. Landscapes mature and thirsty trees start mining humidity from clays. Surrounding advancement weights a communal strata, or even includes resonances that weren't portion of the initial presumptions. In much older industrial properties you also observe differential stuffing under enhancements, or undocumented backfill that never ever compacted.

The obvious signs repeat on their own throughout jobs. Settlement presents as consistent sinking, which is actually rare, or differential motion where sections or concentrated bunches drop faster. Turn is actually just part of the account. Turning at the footing equates right into out-of-plumb wall surfaces and wrenched frames. Shear fracturing in stonework, specifically at window heads as well as edges, has a tendency to align along with movement angles. Slabs on level could break easily, however at tools pads or under shelves they usually spall as well as break up in patches.

An easy vigilance on foundation crack repair. Epoxy shot or even polyurethane foam fits, first and foremost to repair connection or even quit water, however it is not a port. Without addressing the ability of the sustaining soil, an enclosed fracture ends up being a joint hanging around to resume. Structural foundation repair starts along with a weight path audit. You map weight coming from roofing system to ground, and also check out each interface for capacity and also hardness, then you opt for where to step in to make sure that the ground profile you really have can easily bring what the building demands.

Why deep foundation repair is frequently the most affordable lasting path

On newspaper, superficial repairs search cheap. Mudjacking can easily re-level a piece for a fraction of centered job. Added superficial footings seem uncomplicated. The issue is recurrence. If the dirt device always keeps transforming along with moisture swings, or if there is actually a compressible coating you can certainly not address coming from the area, then any type of superficial option is betting versus geology. In business settings, you additionally carry recovery time expenses. Performing it once along with a deep move of lots commonly beats performing it various opportunities along with shorter-lived methods.

Deep groundwork fixing, whether through helical piles, protection piles, or even micropiles, totally resets the tons path in to experienced bearing. The resources differ in exactly how they cultivate capacity, their installation altruisms, sound as well as resonance account, and also how much operating area they need. All three can be put up indoors, around energies, and also in limited heights. Choosing the right way calls for three inputs: a trustworthy soil style, a clear bunch timetable, as well as internet site logistics.

Helical stacks: torque is your friend when you may confirm it

Helical piles, sometimes gotten in touch with helical anchors or turn heaps, are actually steel arrows along with several coils soldered to the top part. Our team install them by turning right into the ground along with a gas ride, measure installment twist, and connect that torque along with bearing capacity. In commercial helical pile installation, that twist correlation is actually certainly not a guess. Our company develop it along with test piles or even draw on records for the details helix geometry and ground profile.

The elegance of helical piles is speed as well as management. There is actually no spoils handling beyond what the shaft displaces. In vulnerable web sites, that means cleaner job and a lot less bring of moist cuttings. Helical piles master clay-baseds and silts where the coil plates may produce predictable end-bearing as well as side resistance. In sands, particularly loose or even collapsible sands, you require careful twist surveillance and also sometimes bigger helices or even additional trigger chase a deeper stratum.

Consider a warehouse retrofit where racking loads multiplied. We set up helical piles with existing slab cuts, progressing twenty to 35 feets up until twist fulfilled the intended for 40 kips allowed every stack along with a safety aspect. The installers enjoyed torque increase continuously. When twist plateaued in a slick clay joint at 18 feets, they carried out certainly not force it. We added an additional lead with a much larger helix and evolved right into the rigid clay-based at 28 feet, where twist ramped once more. That potential to adapt directly defeats precast steered turn in a lot of interior work where space is actually limited and also vibrations are actually certainly not acceptable.

There are limitations. Helical piles struggle with sizable cobble or even stone levels, where the helix may certainly not cut and also often tends to deflect. In firm soils or thick gravels, the twist criteria may exceed practical installment capacity. Rust considerations also matter. In mildly acrid dirts our team specify galvanization or even style sacrificial fullness. In aggressive settings, sleeving or grout columns may incorporate with coils, but then micropiles may be much more efficient.

Resistance heaps: making use of the structure as the jack

Resistance stacks, often phoned push stacks or hydraulically steered steel piers, establish capability by mounting steel pipe sections versus the structure as well as driving all of them to a depth where skin abrasion as well as foot protection equilibrium the used power. In commercial resistance pile installation we commonly preload each pile to a numerous of the style company payload, commonly 1.5 to 2 times, so our company confirm ability sitting. The structure itself provides the reaction during steering, which means our experts require adequate footing durability and in some cases brace reinforcement.

The durability of resistance piles is their portable tools impact and also their functionality in combined loads. If our experts have a slab-on-grade with very little authorization, our experts can cut tiny windows, established braces, as well as push heaps along with gas rams linked to the brace. Our company checked out stress as well as stroke, log rejection depths, and after that lift or stabilize to prepare altitudes. For troubled footings, an adequately developed steel brace disperses bunch and moves it in to the heap without drilling the concrete.

I like protection heaps for therapeutic work at constructing boundaries where access is actually possible and soil strata include lenses of gentle stuffing over denser layers. Due to the fact that we drive to functional rejection, the body normally looks for capable deepness. Where I think twice is when the existing ground is breakable or under-reinforced, or when the property can easily certainly not give adequate reaction to drive the stacks. Because situation, a separate reaction structure or even a different heap kind creates even more feeling. Resonance is actually very little, yet our company still collaborate along with sensitive functions, especially near lab equipment and also information centers.

Micropiles: drill, cement, as well as anchor right into virtually anything

Micropiles are actually small-diameter bored as well as grouted heaps along with steel support inside, either a bar or a steel housing. They beam in ailments that cease various other options: dense crushed rocks, cobbles, clutter fill, karst, or even where you require higher capability in limited area. Micropile installation makes use of exploration that creates cuttings which should be taken care of, and also grout that is actually pumped at tensions modified to the dirt. Our experts count on bond in between cement as well as ground along the heap duration, and also toe bearing where feasible.

In commercial micro pile installation, gears vary coming from sleek, low-clearance units that match through common doors, to bigger tracked devices for exterior job. The trade-offs come down to get access to and capability. Along with a 7 to 10 inch size micropile, capacities of 60 to 200 kips prevail, and greater along with suitable connect lengths in stone. Cement premium issues. We assess cement cyndrical tubes, track record editions and stress, and also in important work our team conduct stress or even squeezing lots examinations on proof piles before production.

One shopping complex venture shows the side scenario. The authentic superficial foundations remained on undocumented filler that included blocks, cement chunks, as well as greats. Helical piles dispersed on the rubble. Protection stacks stalled due to the fact that the footing could possibly certainly not take the reaction without danger of shear. Our company changed to micropiles along with brief casing to cut through the obstructions, placed in to thick indigenous grounds listed below 35 feets, and developed new grade shafts to link the body with each other. The micropiles carried the tons, and the brand-new beams dispersed them throughout even more wall structure duration, reducing anxiety on the old footings.

Micropiles carry versatility in struggling setups, which matters when wall surface bunches include lateral elements. Installers may slant heaps to withstand uplift and lateral powers without the sizable diggings that tiebacks demand. They also act properly near vibration-sensitive tools, as drilling vibrations are actually predictable as well as controllable.

Helical tieback anchors: keeping dirt where it belongs

Retaining wall surfaces, cellar walls, and also digging assistance require support to stand up to sidewise the planet stress. Helical tieback anchors are put up flat or at a shallow angle, after that tensioned to a style tons to keep dirt in location. In commercial helical tieback anchor installation, the same guidelines as upright helical piles use. We evolve the helix in to a capable resisting stratum past the breakdown airplane, reviewed twist, and then lock off at the specified tons utilizing a bearing plate or waler.

Tieback supports are a silent option contrasted to soil nails or punched supports that require grout treatment times. They are especially sensible for retrofits where the wall is actually already deflecting and you require to include capability quickly. On a domestic pump station where the backfill had filled as well as stress went up, our team installed helical tiebacks with wall core holes in a staggered pattern, torqued to capacity in a heavy residue level, and pre-tensioned each support. The wall surface movement supported immediately, within days.

Helical tiebacks are certainly not universal. In stony strata with huge voids, a punched as well as grouted anchor can easily offer even more dependable bond. In really smooth clay-baseds that extend deep, you could require support sizes that are actually impractical to install coming from the site. Consistently model the breakdown wedge carefully. The support's coil should sit past it, or even you are actually simply drawing on the soil that wishes to move.

Choosing among helical piles, resistance piles, micropiles, and also tiebacks

Decision-making begins with the ground. A geotechnical file is mandatory, preferably with borings near the troubled region and lab tests for mark homes and also shear stamina. If you carry out not possess one, plan for extra expedition. Area symptoms can easily misinform. A smooth top 10 feets over heavy sand behaves in different ways than 25 feet of plastic clay over weather-beaten rock.

The design matters equally as a lot. Load immensities, load designs, and the wellness of existing structures dictate what our experts can attach to as well as exactly how. For instance, a thin footing along with low encouragement may not take higher bracket loads from resistance piles. An intensely jam-packed column with eccentricity may demand a matched heap team with helical pile foundations an association beam, certainly not a singular vertical element. Slab-on-grade issues under equipment usually ask for brand new isolated foundations along with stacks, not trying to make a jeopardized slab carry out more.

Site strategies at that point fine-tune the selection. If you require silent, low-vibration methods inside an operating hospital airfoil, helical piles and tieback anchors rise to the top. If the dirts include cobbles and also development fragments, micropiles deserve a closer look. If finances are actually strict as well as the ground is strong, resistance stacks can supply efficiency with straightforward devices. The target is actually not to champion one product, but to map restrictions to capabilities.

Verification is the heart beat of commercial foundation repair

In commercial foundation repair, our company do decline capability through leaflet. Every installment procedure includes built-in proof. Along with helical piles and also helical anchors, installation twist logs, pile geometry, and also torque-to-capacity variables provide us a first line of documentation. Our company typically proof-load an amount of heaps making use of a jack and also adjusted scale to verify performance. With resistance piles, our team steer to refusal tension and also preload to a multiple of solution tons, expecting rebound and creep. Along with micropiles, our company may function squeezing or pressure lots exams, and also when specified we execute integrity contact compelling strategies or even low-strain testing.

Documentation is actually not bureaucracy, it is actually danger management. On one warehouse retrofit, a batch of braces from a 3rd party seller possessed a weld detail that did certainly not match the submittal. The installer acknowledged the distinction during pre-install examinations. Given that our team possessed very clear submittal package deals and hold aspects, our experts paused, traced the discrepancy, and stopped a concern that would have been actually laid to rest in concrete. Great commercial foundation stabilization ventures install those stops: submittal testimonial, preconstruction conference, test stack day, verification examination results, after that production.

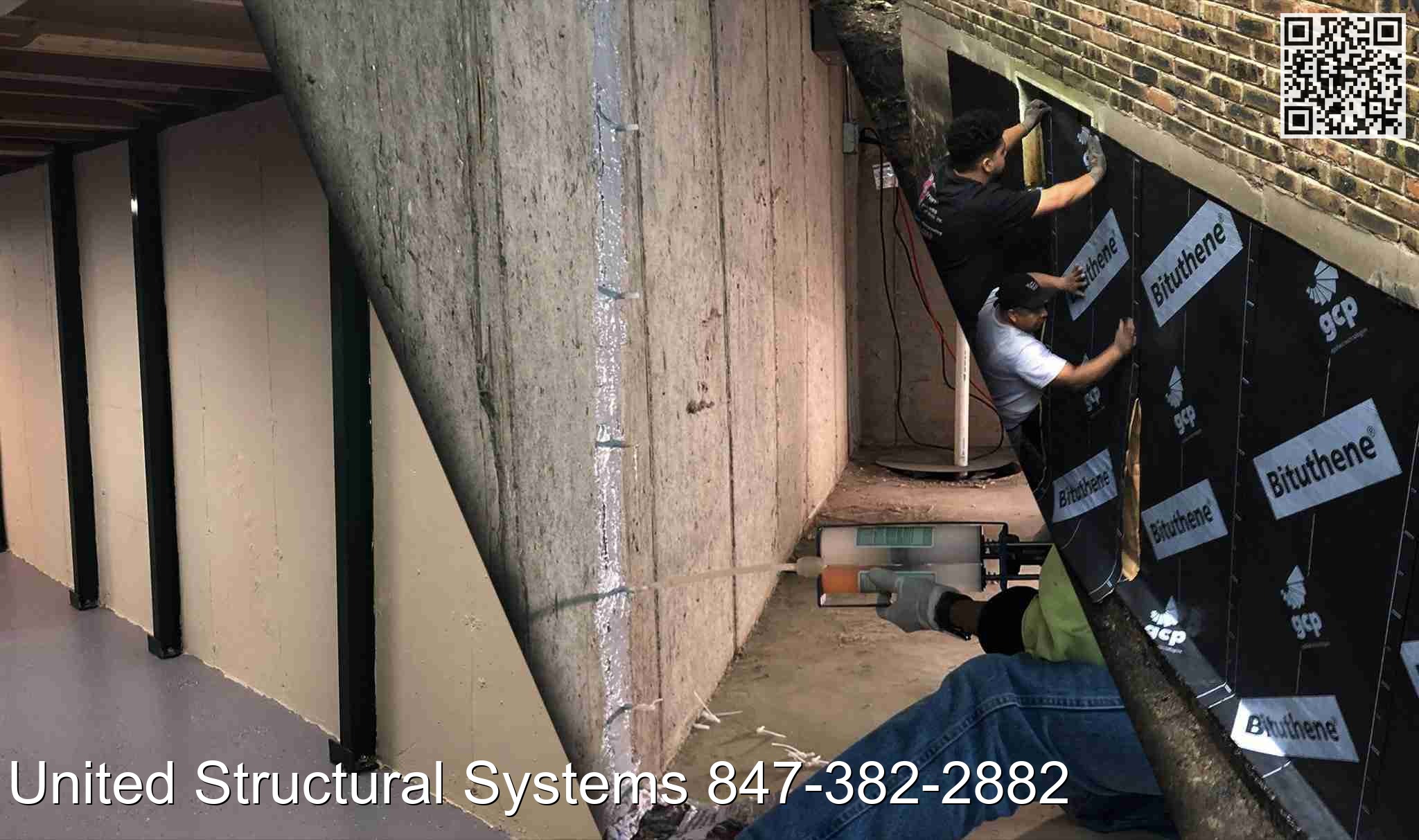

How stablizing socializes along with water and cracks

Water is the silent associate in most structure concerns. Supporting tons without resolving water administration establishes you up for persistent side effects: hydrostatic tension on walls, piece heave in clays that swell when rehydrated, or corrosion at steel elements. As component of deep foundation repair our team commonly combine architectural procedures along with drain and also basement waterproofing enhancements. Perimeter empties, septic tank devices with verboseness, good grading, as well as surface command of downspouts decrease the ground wetness swings that steer movement.

Foundation gap repair service straightens along with these actions. Structural cracks typically receive epoxy injection after stabilization, largely where you need to bring back architectural constancy in an enhanced participant. Non-structural however seeping gaps usually get polyurethane treatment to stop water. The sequence concerns. Mounting or even swiping before injecting avoids tearing a recently bound crack if you transform geometry later. In cellars along with severe wetness, our experts have actually also pointed out water vapor obstacles and under-slab drainage as portion of slab substitute when a new piled beam-and-slab takes over the gravity loads.

Working inside live facilities

Most commercial work happens under tenancy. The most ideal design gains nothing if the owner can easily certainly not maintain operations operating. Helical piles and helical anchors win aspects for low noise and also low spoils. Protection stacks possess a little impact and may function in rooms along with eight-foot ceilings. Micropiles may function within also, yet you require to prepare for spoils monitoring, drilling fluid capture, and ventilation. Night shifts as well as weekend break work lower influence on renters. Transmittable management in health centers incorporates one more layer: damaging air devices, containments, and also dust monitoring.

We as soon as maintained an information center expansion while web servers hummed twelve feets away. Our company cut piece windows, established resistance pile brackets, and drove stacks along with gas rams connected to torque-sensing pumps and low-decibel power devices. Each airlift was actually evaluated in sixteenth ins, along with laser degrees and also split screens. Resonance sensors rested on hosting server racks with alerts set effectively listed below the manufacturer's limits. The job took longer than open-site manufacturing, yet the proprietor certainly never lost a moment of uptime.

Designing lifts as well as recognizing when to stop

Owners like the suggestion of elevating a building back to authentic elevation. At times you can. More frequently you aim for consistent assistance and also partial recuperation. Raising over fragile stonework or weak appearances wagers with internal harm. Differential airlift between neighboring bays can easily produce new anxiety focus. Our experts consider airlifts with intendeds in shared ins and also we make use of a grid of ports and also determines to relocate as an unit, certainly not stack through pile. Communication along with residents concerns. Doors might move, drywall may break, as well as glass could come. These are certainly not failings, yet anticipated effects of geometry correction.

The regulation that has actually served me effectively: elevate the minimal needed to restore functionality as well as drain roads, after that secure the design on firm help. If you are actually chasing the last fourth in while brand-new cracks stumble upon a finished entrance hall, you have shed the story. Structural foundation repair has to do with security and also use first.

Costs, routines, and what travels them

Owners wish numbers early. You may supply selections, but until you have actually decided on a technique as well as confirmed the ground, spreads are going to be broad. Helical piles and also tiebacks generally value properly when gain access to is easy and also soils are friendly. Protection stacks rest likewise, along with the price of brackets and preload time factored in. Micropiles fad higher per pile as a result of drilling time, cement, as well as testing, but may be economical when other techniques demand extensive leveling or even can certainly not obtain ability. Mobilization is an actual pipes item. Little jobs in several mobilizations are actually much less dependable than bundling work.

Schedules rely on permitting, component preparation, as well as testing. Primed steel and customized brackets may hold lead times, though several contractors always keep conventional sizes in inventory. Cement and cement are Go here conveniently accessible, yet onsite testing and also treatment opportunity includes in length for micropiles. If the task consists of helical tieback anchors that need to have lots testing, prepare a time or 2 initially before complete creation. Weather rarely ceases interior deep work, which is actually a lifesaver when the rest of a funds program is actually sliding.

Common mistakes and also just how to avoid them

- Skipping or under-scoping geotechnical exploration. Sparing a few thousand bucks on borings may cost dozens manies thousand in adjustment purchases when the ground unpleasant surprises you. Overloading a feeble ground with hostile jacking for protection heaps. Appreciation the bracket limitations and footing capacity, or you will trade settlement deal for shear. Ignoring corrosion. Ground chemistry can differ all over a site. Assess it, then select finishes, sacrificial density, or cathodic protection where appropriate. Treating crack injection as a building repair. Utilize it as an enhance after loads are actually secured, certainly not alternatively for deep support. Poor information. Without torque logs, tension reports, as well as load test information, you are counting on chance. Inspectors and also potential managers need to have a record that the work executes as designed.

When blending strategies creates sense

Rarely does a task make use of a single resource. Along a mixed-use building with a stepped foundation, our team the moment integrated helical piles under interior level beams, resistance stacks at the outside where the ground was stronger as well as access satisfied brackets, as well as helical tieback anchors to maintain a maintaining wall surface that had actually started to pitch. On the same task, piece substitutes got brand-new beam-and-slab bodies supported on stacks to decouple sensitive tenants from the unpredictable subgrade. That mosaic worked given that each piece dealt with a details trouble with a method that match the constraints.

Micropiles frequently appear as the medical alternative where the various other devices struck blockages. Our team have actually also made use of micropiles as pressure aspects under covers based on uplift, combining them with helical anchors where grounds shift from clay-based to rocks around a brief range. The point is actually to suit the strategy to the wallet. If you are actually picking a singular product before you possess records, you are actually selling, certainly not engineering.

What owners ought to talk to prior to authorizing a plan

Owners do not require to become heap pros, yet a handful of focused concerns lift the entire team. Ask what ground layers carry the load as well as exactly how our experts verified that in the field. Seek the lots pathway coming from the structure into deep blue sea components and also out right into the ground, including braces, limits, and also beams. Ask about confirmation: which tests, what acceptance standards, and also how many. Inquire how water is actually being taken care of to prevent a loyal of the rooting concern. Eventually, ask about post-install monitoring. Basic crack assesses, altitude measures, or telltales on walls give early warnings as well as peace of mind.

The task of expert installers in outcomes

No style makes it through unsatisfactory execution. The very best commercial helical pile installation relies upon staffs that review soils via the ride scalp, that know the distinction between unpleasant clay-based torque and also helix-on-boulder torque. Good resistance pile workers understand exactly how a ground is going to respond as they steer, when to stop briefly, and also just how to adjust airlifts. Micropile groups always keep grout constant, casings tight, and also logs total, at that point protect new job as various other business circulation via. Tieback staffs pressure uniformly and see the wall surface respond.

Choose firms that self-perform or even closely handle their area crews, and that can reveal logbooks, not merely pictures. Throughout preconstruction appointments, listen to how they define breakdown settings and also emergencies. If the discussion revolves merely around ideal situations, you will be actually creating change commands when the ground presents reality.

A closing note on resilience and also maintenance

Deep base devices are greatly hidden after setup, which is actually the point. Think about toughness at concept. Define layers, sleeves, or even grout where rust risk warrants it. Particular limits and brackets to drop water and also enable assessment. Where bases neighbor aggressive defrosting salts or even industrial chemicals, isolate steel coming from visibility. For helical anchors in retaining constructs, provide accessibility to re-tension if potential activity demands it. Maintenance is actually light when the style anticipates the environment.

Deep structure repair work sits at the intersection of geotechnical truth and building and construction materialism. Helical piles, resistance stacks, micropiles, and helical tieback anchors give our team a sturdy collection of choices. The best one depends upon soils, establishment, and web site. Prospered, these bodies maintain structures for decades, rejuvenate serviceability, as well as let proprietors organize improvements rather than going after symptoms. The job is not glittery. It is gauged in upright door frames, level racking, tranquil wall surfaces, and also the absence of brand-new gaps. That is actually results in structural foundation repair, and also it is worth the care it needs to achieve it.